1) Six Sigma is not another quality program. Six Sigma uses your resources to fix identifiable, chronic problems. It proves its value by connecting outcomes to your bottom line.

2) Six Sigma is not theory. It's a practice of discovering the vital few processes that matter most. It defines, measures, analyzes, improves, and controls them to tie quality improvement directly to bottom-line results.

3) Six Sigma is not a training program. Of course, practitioners are trained in the methodology to ensure correct implementation and results.

Here are some facts about the ripple effects of low-sigma performance:

1)A dissatisfied customer will tell nine people about an unhappy experience.

2)The same customer will only tell five people if a problem is handled satisfactorily.

3)Thirty-one percent of customers who experience service problems never register complaints, because it is "too much trouble."

4)Of that 31 percent, as few as 9 percent will do additional business with the company.

Thursday, 19 November 2009

Types of Waste in Project Management

There are different types of waste in the Six Sigma terminology.One of the primary goals of the Lean Six Sigma project management methodology is the elimination and reduction of waste.

These seven types of waste are:

Overproduction - occurs when a product is made without a buyer

Waiting - occurs when a product sits in waiting for processing

Transport - occurs when a product is moved to many different places

Inventory - occurs when a product is stored and it costs money

Over-processing - occurs when a step in the process is unnecessary or redundant

Motion - occurs when people move excessively

Defects - occurs when an error in the process occurs

These seven types of waste are:

Overproduction - occurs when a product is made without a buyer

Waiting - occurs when a product sits in waiting for processing

Transport - occurs when a product is moved to many different places

Inventory - occurs when a product is stored and it costs money

Over-processing - occurs when a step in the process is unnecessary or redundant

Motion - occurs when people move excessively

Defects - occurs when an error in the process occurs

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

What is a Time Value Map?

A time value map can be a very useful tool when utilizing Six Sigma methodology.

A time value map tracks a single work item through its process. It accounts for where time is spent on this action item. The time value map begins with the outset of the work item and it tracks it through delivery to the end user.

The aim of the time value map is to eliminate waste. As you'll remember from Six Sigma and Lean Six Sigma, waste is something that should be avoided at all costs. By tracking where time is spent, processes and tasks that do not contribute to the overall quality of the end product can be eliminated, and the process for that product can be streamlined.

Companies that wish to save money and resources do well to reduce waste in their processes.

The reason a time value map is so crucial to project management is that it allows identification of areas of waste.

Draw the Time Value Map

Now that you know the three categories, you can track each of the activities involved in the work process. You will need to track each activity involved in the work item's process and the time it takes to complete the activity.

The center line is the timeline for the entirety of your project's duration. Above this line, you will chart the activities that are value-added work at the appropriate time on the time line. Below the timeline, you will track the waste. The creator of the chart used two different colors to differentiate between unavoidable and avoidable waste.

Finally, once you have a visualization of the time value in your project, you can begin to eliminate areas of waste and improve the quality and speed of your work item process.

A time value map tracks a single work item through its process. It accounts for where time is spent on this action item. The time value map begins with the outset of the work item and it tracks it through delivery to the end user.

The aim of the time value map is to eliminate waste. As you'll remember from Six Sigma and Lean Six Sigma, waste is something that should be avoided at all costs. By tracking where time is spent, processes and tasks that do not contribute to the overall quality of the end product can be eliminated, and the process for that product can be streamlined.

Companies that wish to save money and resources do well to reduce waste in their processes.

The reason a time value map is so crucial to project management is that it allows identification of areas of waste.

Draw the Time Value Map

Now that you know the three categories, you can track each of the activities involved in the work process. You will need to track each activity involved in the work item's process and the time it takes to complete the activity.

The center line is the timeline for the entirety of your project's duration. Above this line, you will chart the activities that are value-added work at the appropriate time on the time line. Below the timeline, you will track the waste. The creator of the chart used two different colors to differentiate between unavoidable and avoidable waste.

Finally, once you have a visualization of the time value in your project, you can begin to eliminate areas of waste and improve the quality and speed of your work item process.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Wednesday, 18 November 2009

What situations warrant initiation of Six Sigma and/or Lean?

2. You want to reduce the number of defects and improve your image with the customer.

3. You want to spend less money on non-value added activities such as cost of non quality.

4. Some of your clients demand that you continuously improve your processes over time.

5. Even if your operational processes are excellent, you still have opportunities to improve in transactional areas.

6. You want to emphasize the importance of a quality work culture in your organization.

7. You want to gain an edge over your competition in order to charge a premium for your services.

8. You want your managers to make decisions based on facts rather than their "gut" feel all the time.

9. You would like to quantify the benefits realized of improvement opportunities.

10. You don't want to be left behind on the learning curve.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Tuesday, 17 November 2009

DMAIC Versus DMADV

The Similarities of DMAIC and DMADV

- Six Sigma methodologies used to drive defects to less than 3.4 per million opportunities.

- Data intensive solution approaches. Intuition has no place in Six Sigma -- only cold, hard facts.

- Implemented by Green Belts, Black Belts and Master Black Belts.

- Ways to help meet the business/financial bottom-line numbers.

- Implemented with the support of a champion and process owner.

The Differences of DMAIC and DMADV

DMAIC

- Define : Define the project goals and customer (internal and external) deliverables

- Measure : Measure the process to determine current performance

- Analyze : Analyze and determine the root cause(s) of the defects

- Improve : Improve the process by eliminating defects

- Control : Control future process performance

When To Use DMAIC

The DMAIC methodology, instead of the DMADV methodology, should be used when a product or process is in existence at your company but is not meeting customer specification or is not performing adequately.

DMADV

- Define : Define the project goals and customer (internal and external) deliverables

- Measure : Measure and determine customer needs and specifications

- Analyze : Analyze the process options to meet the customer needs

- Design : Design (detailed) the process to meet the customer needs

- Verify : Verify the design performance and ability to meet customer needs

When To Use DMADV

The DMADV methodology, instead of the DMAIC methodology, should be used when:

- A product or process is not in existence at your company and one needs to be developed

- The existing product or process exists and has been optimized (using either DMAIC or not) and still doesn't meet the level of customer specification or six sigma level

- Six Sigma methodologies used to drive defects to less than 3.4 per million opportunities.

- Data intensive solution approaches. Intuition has no place in Six Sigma -- only cold, hard facts.

- Implemented by Green Belts, Black Belts and Master Black Belts.

- Ways to help meet the business/financial bottom-line numbers.

- Implemented with the support of a champion and process owner.

The Differences of DMAIC and DMADV

DMAIC

- Define : Define the project goals and customer (internal and external) deliverables

- Measure : Measure the process to determine current performance

- Analyze : Analyze and determine the root cause(s) of the defects

- Improve : Improve the process by eliminating defects

- Control : Control future process performance

When To Use DMAIC

The DMAIC methodology, instead of the DMADV methodology, should be used when a product or process is in existence at your company but is not meeting customer specification or is not performing adequately.

DMADV

- Define : Define the project goals and customer (internal and external) deliverables

- Measure : Measure and determine customer needs and specifications

- Analyze : Analyze the process options to meet the customer needs

- Design : Design (detailed) the process to meet the customer needs

- Verify : Verify the design performance and ability to meet customer needs

When To Use DMADV

The DMADV methodology, instead of the DMAIC methodology, should be used when:

- A product or process is not in existence at your company and one needs to be developed

- The existing product or process exists and has been optimized (using either DMAIC or not) and still doesn't meet the level of customer specification or six sigma level

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Design for Six Sigma

Six Sigma is certainly a powerful approach for the improvement of business processes, either in service or manufacturing industries, and the DMAIC methodology is proving so effective that it has become the industry standard for quality improvement.

Lean and Six Sigma are integrated, providing tools and techniques to deal with the transactional and efficiency side of manufacturing. TRIZ, the theory of inventive problems solving, is also being integrated within Six Sigma to support the generation of more proactive ideas.

However the design of products and services remains a major challenge, and organisations still continue to propel new products to the market place without a solid guarantee of commercial success. Service by their nature and tradition have never been consciously designed at all!

Design for Six Sigma (DFSS) is an approach that extends the concept of Six Sigma process improvement to that of the design of new products and services, or the re-design of existing items, together with the meticulous design of the supporting processes that deliver these items to the market. Whilst many DFSS methodologies today promote rigorous engineering design with a stronger customer focus, many lack the vision and integration with a successful corporate processes for the introduction of the 'new'.

The company of tomorrow with a successful DFSS programme that extends from the board room down to the mail room and out to the customer will reap the rewards from the rapid development and introduction of products and service that excite the customer and deliver excellent sigma performance, right from the start.

Lean and Six Sigma are integrated, providing tools and techniques to deal with the transactional and efficiency side of manufacturing. TRIZ, the theory of inventive problems solving, is also being integrated within Six Sigma to support the generation of more proactive ideas.

However the design of products and services remains a major challenge, and organisations still continue to propel new products to the market place without a solid guarantee of commercial success. Service by their nature and tradition have never been consciously designed at all!

Design for Six Sigma (DFSS) is an approach that extends the concept of Six Sigma process improvement to that of the design of new products and services, or the re-design of existing items, together with the meticulous design of the supporting processes that deliver these items to the market. Whilst many DFSS methodologies today promote rigorous engineering design with a stronger customer focus, many lack the vision and integration with a successful corporate processes for the introduction of the 'new'.

The company of tomorrow with a successful DFSS programme that extends from the board room down to the mail room and out to the customer will reap the rewards from the rapid development and introduction of products and service that excite the customer and deliver excellent sigma performance, right from the start.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Six Sigma TRIZ

Successful Inventive Problem Solving

TRIZ (or TIPS) comes from the Russian for 'Theory of Inventive Problem Solving' and is a powerful problem-solving toolkit that complements the more traditional Six Sigma Black Belt skills. Black and Green Belts often use process improvement or design methodologies such as DMAIC and DMADV, both of which rely heavily on solving business problems by optimisation alone. Unfortunately this is sometimes not enough and we need a more creative or inventive solution. TRIZ can provide a great deal to help Black Belts and their teams adopt the new paradigm of inventive and creative thought!

TRIZ and all its component parts were developed by Genrich Altshuller and a group of many others over a period of fifty years from the late 1940's, using work undertaken to study more than 2.5 million patents. By analysing technical inventions Altshuller was able to realise several laws, principles and algorithms for problem solving (such as ARIZ) based on the evolution of technical systems. His approach has been used extensively in Russia for decades, and is now being applied by engineers world wide to aid the solution of the increasingly complex design of products and systems.

The laws and principles of inventive problem solving are the product of a great deal of work undertaken by Altshuller in his native Russia, and although much has only recently been translated into English, the ideas are now being successfully applied across both Europe and the United States. Many organisations today realise that Six Sigma provides an excellent framework for quality and business improvement, and approaches such as TRIZ and Lean manufacturing can be readily integrated into DMAIC and DMADV to enhance the overall impact.

TRIZ (or TIPS) comes from the Russian for 'Theory of Inventive Problem Solving' and is a powerful problem-solving toolkit that complements the more traditional Six Sigma Black Belt skills. Black and Green Belts often use process improvement or design methodologies such as DMAIC and DMADV, both of which rely heavily on solving business problems by optimisation alone. Unfortunately this is sometimes not enough and we need a more creative or inventive solution. TRIZ can provide a great deal to help Black Belts and their teams adopt the new paradigm of inventive and creative thought!

TRIZ and all its component parts were developed by Genrich Altshuller and a group of many others over a period of fifty years from the late 1940's, using work undertaken to study more than 2.5 million patents. By analysing technical inventions Altshuller was able to realise several laws, principles and algorithms for problem solving (such as ARIZ) based on the evolution of technical systems. His approach has been used extensively in Russia for decades, and is now being applied by engineers world wide to aid the solution of the increasingly complex design of products and systems.

The laws and principles of inventive problem solving are the product of a great deal of work undertaken by Altshuller in his native Russia, and although much has only recently been translated into English, the ideas are now being successfully applied across both Europe and the United States. Many organisations today realise that Six Sigma provides an excellent framework for quality and business improvement, and approaches such as TRIZ and Lean manufacturing can be readily integrated into DMAIC and DMADV to enhance the overall impact.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Thursday, 12 November 2009

Six Sigma Certification

Attaining a recognised qualification in Six Sigma - be it Green Belt, Black Belt, Master Black Belt or Champion - is a necessary step for any quality practitioner. But what exactly does it involve?

Many questions arise in the minds of six sigma certification candidates.Here is brief outline of a few fundamental questions that are frequently asked about Six Sigma Certification.

What is Certification?

Six Sigma Certification is documented proof that a person has acquired certain standardized capabilities with regard to the quality management technique that, when applied, works towards error/defect elimination and prevention. However, the certificate does not guarantee that a candidate has implementation skills, but only certifies competency in the subject matter.

One can attain certification in any of the key roles (Black Belt, Master Black Belt, Champion, etc.).

How do I become Six Sigma certified?

Six Sigma Certification typically involves studying the related subject matter and passing an exam. Training institutes or companies provide certification tests and six sigma training courses. It is not unusual for new companies to have their employees test on a training institutes' tests. This completes the first part of the written test in the candidate's proficiency in the subject matter. Now comes the real test! Once having passed the written test, The candidate must work hands on a project or two in a practical environment. In this situation, the candidate must demonstrate that he or she is competent enough to implement the knowledge acquired in classroom six sigma training.

During the practical part of the exam, there is no benchmark for what passes or not. Not just this, but some companies may accept just one project and some others may not. This means that out of the three critical aspects of six sigma certification training, the written exam and the practical competency demonstration, a crucial third one may be said to be lacking seriously or non-existent, unless it becomes standardized. To complicate matters, there is no one single body to regulate or standardize all the critical aspects of six sigma certification.

Do I need a Six Sigma Certification?

This is any individual's professional decision. Anyone wanting to get six sigma certification will need to think seriously about it. Sometimes candidates are chosen (or compelled) by their employer to take six sigma training and thereby attain six sigma certification. But many times, it is the other way around. Someone may decide to pursue six sigma certification for reasons such as attainment of a raise or promotion. Another may be prompted by the fact that six sigma certification will enhance their marketability. While each reason is an individual one, candidates must be result oriented, highly motivated in order to be successful.

What will certification cost me?

Many questions arise in the minds of six sigma certification candidates.Here is brief outline of a few fundamental questions that are frequently asked about Six Sigma Certification.

What is Certification?

Six Sigma Certification is documented proof that a person has acquired certain standardized capabilities with regard to the quality management technique that, when applied, works towards error/defect elimination and prevention. However, the certificate does not guarantee that a candidate has implementation skills, but only certifies competency in the subject matter.

One can attain certification in any of the key roles (Black Belt, Master Black Belt, Champion, etc.).

How do I become Six Sigma certified?

Six Sigma Certification typically involves studying the related subject matter and passing an exam. Training institutes or companies provide certification tests and six sigma training courses. It is not unusual for new companies to have their employees test on a training institutes' tests. This completes the first part of the written test in the candidate's proficiency in the subject matter. Now comes the real test! Once having passed the written test, The candidate must work hands on a project or two in a practical environment. In this situation, the candidate must demonstrate that he or she is competent enough to implement the knowledge acquired in classroom six sigma training.

During the practical part of the exam, there is no benchmark for what passes or not. Not just this, but some companies may accept just one project and some others may not. This means that out of the three critical aspects of six sigma certification training, the written exam and the practical competency demonstration, a crucial third one may be said to be lacking seriously or non-existent, unless it becomes standardized. To complicate matters, there is no one single body to regulate or standardize all the critical aspects of six sigma certification.

Do I need a Six Sigma Certification?

This is any individual's professional decision. Anyone wanting to get six sigma certification will need to think seriously about it. Sometimes candidates are chosen (or compelled) by their employer to take six sigma training and thereby attain six sigma certification. But many times, it is the other way around. Someone may decide to pursue six sigma certification for reasons such as attainment of a raise or promotion. Another may be prompted by the fact that six sigma certification will enhance their marketability. While each reason is an individual one, candidates must be result oriented, highly motivated in order to be successful.

What will certification cost me?

Again, this is a highly subjective question. It could cost you anywhere from $0 to $30,000 per person, depending on where you receive six sigma training. Again, the decision as to the trainer, location, and online or offline six sigma training method are other considerations as to cost.

What worked for one person may not work for another. When contemplating six sigma certification, there really are no generalizations that can be made. It all depends on who individual capabilities, location, and to some extent, your position in the corporation (or lack thereof).

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Tuesday, 10 November 2009

When to Use Process Capability Charts

Process capability attempts to answer the question: can we consistently meet customer requirements?

The number one limitation of process capability indices is that they are meaningless if the data is not from a controlled process. The reason is simple: process capability is a prediction, and you can only predict something that is stable.

In order to estimate process capability, you must know the location, spread, and shape of the process distribution. These parameters are, by definition, changing in an out of control process. Therefore, only use Process Capability indices if the process is in control for an extended period.

The number one limitation of process capability indices is that they are meaningless if the data is not from a controlled process. The reason is simple: process capability is a prediction, and you can only predict something that is stable.

In order to estimate process capability, you must know the location, spread, and shape of the process distribution. These parameters are, by definition, changing in an out of control process. Therefore, only use Process Capability indices if the process is in control for an extended period.

The same argument holds for a Histogram. If the purpose of creating a histogram is to see the "shape" of the process, it will be very misleading if the process is not stable. For example, a process that is stable could very well have the same histogram as a process undergoing a trend, since the only difference in the data would be the order of the points. Since the histogram does not consider the sequence of the points, you would see no difference between histograms.

Upon further investigation, however, it is apparent from the control chart of this process data (shown below) that the process is not in statistical control. Thus, while we can assert the sample data is Normally distributed, we can make no assertions about the more general (and relevant) process behavior, including its Process Capability index.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Pros and Cons of Six Sigma

The following aspects of the Six Sigma strategy are not accentuated in previous quality improvement initiatives.

2) Six Sigma strategy places an unprecedented importance on strong and passionate leadership and the support required for its successful deployment

3) Six Sigma methodology of problem solving integrates the human elements(culture change, customer focus, belt system infrastructure, etc.) and process elements(process management, statistical analysis of process data, measurement system analysis, etc.) of improvement.

4) Six Sigma methodology utilises the tools and techniques for fixing problems in business processes in a sequential and disciplined fashion. Each tool and technique within the Six Sigma methodology has a role to play and when, where, why and how these tools or techniques should be applied is the difference between success and failure of a Six Sigma project.

5) Six Sigma creates an infrastructure of Champions, Master Black Belts (MBBs), Black Belts (BBs) and Green Belts (GBs) that lead, deploy and implement the approach.

6) Six Sigma emphasises the importance of data and decision making based on facts and data rather than assumptions and hunches ! Six Sigma forces people to put measurements in place. Measurement must be considered as a part of the culture change.

7) Six Sigma utilises the concept of statistical thinking and encourages the application of well-proven statistical tools and techniques for defect reduction through process variability reduction methods (e.g.: statistical process control and design of experiments)

The following are some of the limitations of Six Sigma which creates opportunities for future research.

1) The challenge of having quality data available, especially in processes where no data is available to begin with (sometimes this task could take the largest proportion of the project time)

2) The right selection and prioritisation of projects is one of the critical success factors of a Six Sigma program. The priorit isation of projects in many organisations is still based on pure subjective judgement. Very few powerful tools are available for prioritising projects and this should be the major thrust for research in the future.

3) The statistical definition of Six Sigma is 3.4 defects or failures per million opportunities. In service processes, a defect may be defined as anything which does not meet customer needs or expectations. It would be illogical to assume that all defects are equally bad when we calculate the Sigma Capability level of a process. For instance, a defect in a hospital could be a wrong admission procedure,misdiagnosis, lack of training required by a staff member,misbehaviour of staff members, unwillingness to help patients when they have specific queries, etc.

4) Assumption of 1.5 sigma shift for all business processes does not make much sense. This particular issue should be dealt with extra caution as a small shift in sigma could lead to erroneous defect calculations.

5) Non-standardisation procedures in the certification process of Black belts, Green belts, etc. Research has shown that the skills and expertise developed by Black belts/Green belts are inconsistent across companies and are dependent a great deal on the certification body. Black belts believe they know all the practical aspects of advanced quality improvement methods such as Design of Experiments, Robust Design, Response Surface Methodology, Statistical Process Control and Reliability, when in fact they have barely scratched the surface.

6) Six Sigma can easily digress into a bureaucratic exercise if the focus is on such things as the number of trained Black Belts and Green Belts, number of projects completed, etc. instead of bottomline savings.

7)There is an overselling of Six Sigma by too many consulting firms. Many of them claim expertise in Six Sigma when they barely understand the tools and techniques and the Six Sigma roadmap.

8) The relationship between Cost of Poor Quality (COPQ) and Process Sigma Quality Level requires more justification.

1) Six Sigma strategy places a clear focus on achieving measurable and quantifiable financial returns to the bottom-line of an organisation . No Six Sigma project is approved unless the bottom-line impact has been clearly identified and defined.

2) Six Sigma strategy places an unprecedented importance on strong and passionate leadership and the support required for its successful deployment

3) Six Sigma methodology of problem solving integrates the human elements(culture change, customer focus, belt system infrastructure, etc.) and process elements(process management, statistical analysis of process data, measurement system analysis, etc.) of improvement.

4) Six Sigma methodology utilises the tools and techniques for fixing problems in business processes in a sequential and disciplined fashion. Each tool and technique within the Six Sigma methodology has a role to play and when, where, why and how these tools or techniques should be applied is the difference between success and failure of a Six Sigma project.

5) Six Sigma creates an infrastructure of Champions, Master Black Belts (MBBs), Black Belts (BBs) and Green Belts (GBs) that lead, deploy and implement the approach.

6) Six Sigma emphasises the importance of data and decision making based on facts and data rather than assumptions and hunches ! Six Sigma forces people to put measurements in place. Measurement must be considered as a part of the culture change.

7) Six Sigma utilises the concept of statistical thinking and encourages the application of well-proven statistical tools and techniques for defect reduction through process variability reduction methods (e.g.: statistical process control and design of experiments)

The following are some of the limitations of Six Sigma which creates opportunities for future research.

1) The challenge of having quality data available, especially in processes where no data is available to begin with (sometimes this task could take the largest proportion of the project time)

2) The right selection and prioritisation of projects is one of the critical success factors of a Six Sigma program. The priorit isation of projects in many organisations is still based on pure subjective judgement. Very few powerful tools are available for prioritising projects and this should be the major thrust for research in the future.

3) The statistical definition of Six Sigma is 3.4 defects or failures per million opportunities. In service processes, a defect may be defined as anything which does not meet customer needs or expectations. It would be illogical to assume that all defects are equally bad when we calculate the Sigma Capability level of a process. For instance, a defect in a hospital could be a wrong admission procedure,misdiagnosis, lack of training required by a staff member,misbehaviour of staff members, unwillingness to help patients when they have specific queries, etc.

4) Assumption of 1.5 sigma shift for all business processes does not make much sense. This particular issue should be dealt with extra caution as a small shift in sigma could lead to erroneous defect calculations.

5) Non-standardisation procedures in the certification process of Black belts, Green belts, etc. Research has shown that the skills and expertise developed by Black belts/Green belts are inconsistent across companies and are dependent a great deal on the certification body. Black belts believe they know all the practical aspects of advanced quality improvement methods such as Design of Experiments, Robust Design, Response Surface Methodology, Statistical Process Control and Reliability, when in fact they have barely scratched the surface.

6) Six Sigma can easily digress into a bureaucratic exercise if the focus is on such things as the number of trained Black Belts and Green Belts, number of projects completed, etc. instead of bottomline savings.

7)There is an overselling of Six Sigma by too many consulting firms. Many of them claim expertise in Six Sigma when they barely understand the tools and techniques and the Six Sigma roadmap.

8) The relationship between Cost of Poor Quality (COPQ) and Process Sigma Quality Level requires more justification.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Blackbelts - Who and How?

While Six Sigma Black Belts are generally given credit for their expertise in analytical, statistical and problem solving techniques, successful Black Belts must be much more than technical experts

.

The advancement of an organization from a nominal 3.5 Sigma to Six Sigma represents a vast organizational (and cultural) change. Black Belts are primarily Change Agents.

Effective Change Agents are:

1) Positive Thinkers: Black Belts need to have faith in management and in the direction of the business and its Six Sigma program. They must be upbeat and optimistic about the program success, or they risk undermining management or the Six Sigma initiative. They need to exude self-confidence, without the pitfalls of being overbearing, defensive or self-righteous. Proper Management support and vision allow Black Belts to both believe in and experience their potential as Change Agents.

2) Risk Takers: Black Belts need to be comfortable as Change Agents. While ineffective Change Agents agonizes over implementing change, effective Change Agents relish it. They enjoy the excitement and the challenge of "making things happen" and "grabbing the bull by the horns". They know that change is necessary for the company and the customers' sake; and that change is inevitable, given the competitive market. Only by leading the change can we hope to steer its outcome. The effective Change Agent wants to lead the charge.

3) Good Communicators: An effective Black Belt needs to be capable of distilling a vast amount of technical material in an easily comprehensible fashion to team members, Sponsors, Champions and management. Many of these personnel will have only minimal training (Green Belt or Champion level) in statistical techniques, if any at all. The Black Belt that can clearly and succinctly describe to the team why, for example, a designed experiment is better than one-factor-at-a-time experimentation will strengthen the team and shorten its project completion time.

Of course, being a good communicator is much more than just being capable of distilling technical material. An effective Change Agent must also comprehend and appreciate others' concerns. These concerns must be responded to in a thorough, respectful and thoughtful manner.

4) Respected by Peers: It is often said that an individual's position in an organization can be either earned or granted, but that true power must be earned. Effective Change Agents have earned the respect of others in the organization by their hard work and effective communication. Those new to an organization, or who have not gained respect from others, will find it harder to implement changes.

5) Leaders: Black Belts will often serve as Team Leaders; other times they need to show respect to others (and true leadership) by allowing them to assume leadership roles. First wave Black Belts will also serve as role models and mentors for Green Belts and subsequent waves of Black Belts.

Many of these Change Agent skills are facets of one's personalities, but they can be supported through awareness training, management policy, and coaching and mentoring by Master Black Belts and Champions.

The best Black Belts are those individuals who show a balance between these softer attributes and the technical skills described in the Body of Knowledge.

Many firms demand demonstration of these Change Agent attributes, through work history and personal recommendations, as a pre-requisite for consideration of Black Belt candidates.

.

The advancement of an organization from a nominal 3.5 Sigma to Six Sigma represents a vast organizational (and cultural) change. Black Belts are primarily Change Agents.

Effective Change Agents are:

1) Positive Thinkers: Black Belts need to have faith in management and in the direction of the business and its Six Sigma program. They must be upbeat and optimistic about the program success, or they risk undermining management or the Six Sigma initiative. They need to exude self-confidence, without the pitfalls of being overbearing, defensive or self-righteous. Proper Management support and vision allow Black Belts to both believe in and experience their potential as Change Agents.

2) Risk Takers: Black Belts need to be comfortable as Change Agents. While ineffective Change Agents agonizes over implementing change, effective Change Agents relish it. They enjoy the excitement and the challenge of "making things happen" and "grabbing the bull by the horns". They know that change is necessary for the company and the customers' sake; and that change is inevitable, given the competitive market. Only by leading the change can we hope to steer its outcome. The effective Change Agent wants to lead the charge.

3) Good Communicators: An effective Black Belt needs to be capable of distilling a vast amount of technical material in an easily comprehensible fashion to team members, Sponsors, Champions and management. Many of these personnel will have only minimal training (Green Belt or Champion level) in statistical techniques, if any at all. The Black Belt that can clearly and succinctly describe to the team why, for example, a designed experiment is better than one-factor-at-a-time experimentation will strengthen the team and shorten its project completion time.

Of course, being a good communicator is much more than just being capable of distilling technical material. An effective Change Agent must also comprehend and appreciate others' concerns. These concerns must be responded to in a thorough, respectful and thoughtful manner.

4) Respected by Peers: It is often said that an individual's position in an organization can be either earned or granted, but that true power must be earned. Effective Change Agents have earned the respect of others in the organization by their hard work and effective communication. Those new to an organization, or who have not gained respect from others, will find it harder to implement changes.

5) Leaders: Black Belts will often serve as Team Leaders; other times they need to show respect to others (and true leadership) by allowing them to assume leadership roles. First wave Black Belts will also serve as role models and mentors for Green Belts and subsequent waves of Black Belts.

Many of these Change Agent skills are facets of one's personalities, but they can be supported through awareness training, management policy, and coaching and mentoring by Master Black Belts and Champions.

The best Black Belts are those individuals who show a balance between these softer attributes and the technical skills described in the Body of Knowledge.

Many firms demand demonstration of these Change Agent attributes, through work history and personal recommendations, as a pre-requisite for consideration of Black Belt candidates.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

When to Use an Attribute Chart

Only Attributes data can be applied to an Attributes control chart.

To see the differences between various attribute charts, let's consider an example of the errors in an accounting process, where each month we process a certain number of transactions.

1) The Np-Chart monitors the number of times a condition occurs, relative to a constant sample size, when each sample can either have this condition, or not have this condition. For our example, we would sample a set number of transactions each month from all the transactions that occurred, and from this sample count the number of transactions that had one or more errors. We would then track on the control chart the number of transactions with errors per month.

2) The p-Chart monitors the percent of samples having the condition, relative to either a fixed or varying sample size, when each sample can either have this condition, or not have this condition. For our example, we might choose to look at all the transactions in the month (since that would vary from month to month), or a set number of samples, whichever we prefer. From this sample, we would count the number of transactions that had one or more errors. We would then track on the control chart the percent of transactions with errors per month.

3) The c-Chart monitors the number of times a condition occurs, relative to a constant sample size. In this case, a given sample can have more than one instance of the condition, in which case we count all the times it occurs in the sample. For our example, we would sample a set number of transactions each month from all the transactions that occurred, and from this sample count the total number of errors in all the transactions. We would then track on the control chart the number of errors in all the sampled transactions per month.

4) The u-Chart monitors the percent of samples having the condition, relative to either a fixed or varying sample size. In this case, a given sample can have more than one instance of the condition, in which case we count all the times it occurs in the sample. For our example, we might choose to look at all the transactions in the month (since that would vary month to month), or a set number of samples, whichever we prefer. From this sample, we count the total number of errors in all the transactions. We would then track on the control chart the number of errors per transactions per month.

To see the differences between various attribute charts, let's consider an example of the errors in an accounting process, where each month we process a certain number of transactions.

1) The Np-Chart monitors the number of times a condition occurs, relative to a constant sample size, when each sample can either have this condition, or not have this condition. For our example, we would sample a set number of transactions each month from all the transactions that occurred, and from this sample count the number of transactions that had one or more errors. We would then track on the control chart the number of transactions with errors per month.

2) The p-Chart monitors the percent of samples having the condition, relative to either a fixed or varying sample size, when each sample can either have this condition, or not have this condition. For our example, we might choose to look at all the transactions in the month (since that would vary from month to month), or a set number of samples, whichever we prefer. From this sample, we would count the number of transactions that had one or more errors. We would then track on the control chart the percent of transactions with errors per month.

3) The c-Chart monitors the number of times a condition occurs, relative to a constant sample size. In this case, a given sample can have more than one instance of the condition, in which case we count all the times it occurs in the sample. For our example, we would sample a set number of transactions each month from all the transactions that occurred, and from this sample count the total number of errors in all the transactions. We would then track on the control chart the number of errors in all the sampled transactions per month.

4) The u-Chart monitors the percent of samples having the condition, relative to either a fixed or varying sample size. In this case, a given sample can have more than one instance of the condition, in which case we count all the times it occurs in the sample. For our example, we might choose to look at all the transactions in the month (since that would vary month to month), or a set number of samples, whichever we prefer. From this sample, we count the total number of errors in all the transactions. We would then track on the control chart the number of errors per transactions per month.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Six Sigma - Infrastructure

A very powerful feature of Six Sigma is the creation of an infrastructure to ensure that performance improvement activities have the necessary resources.

Failure to provide this infrastructure is the #1 reason why 80% of all TQM implementations failed in the past. Six Sigma makes improvement and change the full-time job of a small but critical percentage of the organization's personnel. These full time change agents are the catalyst that institutionalizes change.

Figure below illustrates the required human resource commitment required by Six Sigma.

Failure to provide this infrastructure is the #1 reason why 80% of all TQM implementations failed in the past. Six Sigma makes improvement and change the full-time job of a small but critical percentage of the organization's personnel. These full time change agents are the catalyst that institutionalizes change.

Figure below illustrates the required human resource commitment required by Six Sigma.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Implementation of Six Sigma

The steps required to successfully implement Six Sigma are -

1. Successful performance improvement must begin with senior leadership. Start by providing senior leadership with training in the principles and tools they need to prepare their organization for success. Simultaneously, steps are taken to "soft-wire" the organization and to cultivate an environment for innovation and creativity. This involves reducing levels of organizational hierarchy, removing procedural barriers to experimentation and change, and a variety of other changes designed to make it easier to try new things without fear of reprisal.

2. Systems are developed for establishing close communication with customers, employees, and suppliers. This includes developing rigorous methods of obtaining and evaluating customer, employee and supplier input. Base line studies are conducted to determine the starting point and to identify cultural, policy, and procedural obstacles to success.

3. Training needs are rigorously assessed. Remedial skills education is provided to assure that adequate levels of literacy and numeracy are possessed by all employees. Top-to-bottom training is conducted in systems improvement tools, techniques, and philosophies.

4. A framework for continuous process improvement is developed, along with a system of indicators for monitoring progress and success. Six Sigma metrics focus on the organization's strategic goals, drivers, and key business processes.

5. Business processes to be improved are chosen by management, and by people with intimate process knowledge at all levels of the organization. Six Sigma projects are conducted to improve business performance linked to measurable financial results. This requires knowledge of the organization's constraints.

6. Six Sigma projects are conducted by individual employees and teams led by Green Belts and assisted by Black Belts.

1. Successful performance improvement must begin with senior leadership. Start by providing senior leadership with training in the principles and tools they need to prepare their organization for success. Simultaneously, steps are taken to "soft-wire" the organization and to cultivate an environment for innovation and creativity. This involves reducing levels of organizational hierarchy, removing procedural barriers to experimentation and change, and a variety of other changes designed to make it easier to try new things without fear of reprisal.

2. Systems are developed for establishing close communication with customers, employees, and suppliers. This includes developing rigorous methods of obtaining and evaluating customer, employee and supplier input. Base line studies are conducted to determine the starting point and to identify cultural, policy, and procedural obstacles to success.

3. Training needs are rigorously assessed. Remedial skills education is provided to assure that adequate levels of literacy and numeracy are possessed by all employees. Top-to-bottom training is conducted in systems improvement tools, techniques, and philosophies.

4. A framework for continuous process improvement is developed, along with a system of indicators for monitoring progress and success. Six Sigma metrics focus on the organization's strategic goals, drivers, and key business processes.

5. Business processes to be improved are chosen by management, and by people with intimate process knowledge at all levels of the organization. Six Sigma projects are conducted to improve business performance linked to measurable financial results. This requires knowledge of the organization's constraints.

6. Six Sigma projects are conducted by individual employees and teams led by Green Belts and assisted by Black Belts.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Six Sigma's magic

Six Sigma's magic isn't in statistical or high-tech razzle-dazzle. Six Sigma relies on tried and true methods that have been around for decades. In fact, Six Sigma discards a great deal of the complexity that characterized Total Quality Management (TQM).

Six Sigma takes a handful of proven methods and trains a small cadre of in-house technical leaders, known as Six Sigma Black Belts, to a high level of proficiency in the application of these techniques. To be sure, some of the methods used by Black Belts are highly advanced, including the use of up-to-date computer technology.

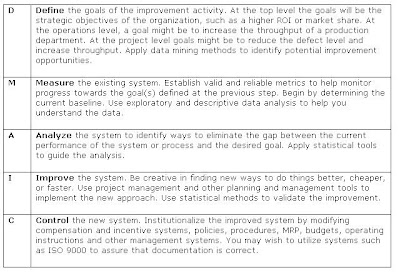

But the tools are applied within a simple performance improvement model known as DMAIC,

Define-Measure-Analyze-Improve-Control. DMAIC can be described as follows:

Six Sigma takes a handful of proven methods and trains a small cadre of in-house technical leaders, known as Six Sigma Black Belts, to a high level of proficiency in the application of these techniques. To be sure, some of the methods used by Black Belts are highly advanced, including the use of up-to-date computer technology.

But the tools are applied within a simple performance improvement model known as DMAIC,

Define-Measure-Analyze-Improve-Control. DMAIC can be described as follows:

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Sunday, 8 November 2009

PICK Charts

A PICK Chart is used when a team is faced with multiple improvement ideas. The tool helps solve such issues related to deciding which ideas should be implemented. There are four categories on a 2 x 2 matrix. On the scale, the horizontal axis has scale of payoff or benefits and vertical axis has ease of implementation. Next, the decision needs to be taken as to where the idea falls on the PICK Chart by categorizing them under actions such as Possible, Implement, Challenge, and Kill.

The actions are classified as:

A) Low payoff, easy to do – Possible

B) High payoff, easy to do – Implement

C) High payoff, hard to do – Challenge

D) Low payoff, hard to do – Kill

The vertical axis represents ease of implementation that would include an assessment of cost to implement as well. The more expensive actions are more difficult to implement. For a look at sample PICK Chart templates, refer to this article containing links to downloadable Six Sigma templates.

Usage of PICK Charts

The PICK Chart tool is used when evaluating pre-process unprocessed data. The method enables the user to reduce huge amounts of raw data to get to the base problem. The PICK Chart is most frequently used during the pre-processing phase of Six Sigma after the data collection stage.

There are numerous techniques to process data. One of the ways is to focus on a sample and condense the information for a particular purpose. The process starts by assessing customer feedback. The data is broken down into the needs and is often known as pre-processing.

The step mainly includes analyzing consumer responses and extracting key phrases to verify the needs and their context. The records are kept systematically and highlighted in different colors as per their needs and context to ensure traceability to their unique starting place. This will help in organizing the data for further characterization.

After the completion of the stage, if there is still a lot of data left, it may be compulsory to cut the data further while maintaining an appropriate representative sample. This helps save energy and time in the long run.

The steps that need to be followed to create a PICK Chart are:

Step 1: On a chart, place the subject question. The question needs to be asked and answered by the team at different stages to be sure that the data that is collected is relevant.

Step 2: Put each component of the data on a different note like a post-it or small cards. These notes should be arranged on the left side of the chart.

Step 3: Each team member must read all notes individually and consider its importance. The team member should decide whether the element should or should not remain a fraction of the significant sample. The notes are then removed and moved to the other side of the chart. Now, the data is condensed enough to be processed for a particular purpose by means of tools like Net-Touch, Affinity Diagrams, or KJ Analysis.

- All team members write open-ended questions that are addressed to the learning objectives.

- All team members have their own notes.

- The mediator randomly picks one note from the group.

- After the note is read, the mediator asks the group if anyone has a query that belongs with the one just read.

- Since all team members are familiar with their own notes, efficiency is provided.

- The mediator collects all notes that are offered and forms a cluster with the original note.

- The step is repeated until all notes have set themselves in the cluster.

- These large clusters are subdivided in small groups and have titles

The actions are classified as:

A) Low payoff, easy to do – Possible

B) High payoff, easy to do – Implement

C) High payoff, hard to do – Challenge

D) Low payoff, hard to do – Kill

The vertical axis represents ease of implementation that would include an assessment of cost to implement as well. The more expensive actions are more difficult to implement. For a look at sample PICK Chart templates, refer to this article containing links to downloadable Six Sigma templates.

Usage of PICK Charts

The PICK Chart tool is used when evaluating pre-process unprocessed data. The method enables the user to reduce huge amounts of raw data to get to the base problem. The PICK Chart is most frequently used during the pre-processing phase of Six Sigma after the data collection stage.

There are numerous techniques to process data. One of the ways is to focus on a sample and condense the information for a particular purpose. The process starts by assessing customer feedback. The data is broken down into the needs and is often known as pre-processing.

The step mainly includes analyzing consumer responses and extracting key phrases to verify the needs and their context. The records are kept systematically and highlighted in different colors as per their needs and context to ensure traceability to their unique starting place. This will help in organizing the data for further characterization.

After the completion of the stage, if there is still a lot of data left, it may be compulsory to cut the data further while maintaining an appropriate representative sample. This helps save energy and time in the long run.

The steps that need to be followed to create a PICK Chart are:

Step 1: On a chart, place the subject question. The question needs to be asked and answered by the team at different stages to be sure that the data that is collected is relevant.

Step 2: Put each component of the data on a different note like a post-it or small cards. These notes should be arranged on the left side of the chart.

Step 3: Each team member must read all notes individually and consider its importance. The team member should decide whether the element should or should not remain a fraction of the significant sample. The notes are then removed and moved to the other side of the chart. Now, the data is condensed enough to be processed for a particular purpose by means of tools like Net-Touch, Affinity Diagrams, or KJ Analysis.

- All team members write open-ended questions that are addressed to the learning objectives.

- All team members have their own notes.

- The mediator randomly picks one note from the group.

- After the note is read, the mediator asks the group if anyone has a query that belongs with the one just read.

- Since all team members are familiar with their own notes, efficiency is provided.

- The mediator collects all notes that are offered and forms a cluster with the original note.

- The step is repeated until all notes have set themselves in the cluster.

- These large clusters are subdivided in small groups and have titles

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Kaizen Philosophy

Kaizen means improvements. Kaizen philosophy is practiced in industry for getting big cumulative organizational level improvement by achieving small improvements at the team member level first. For leading a Kaizen, you need to be a disciplined leader who can work with the team and is capable of bringing changes.

What is Kaizen ?

The Japanese word “Kaizen” means “improvement.” The Kaizen philosophy is applied for manufacturing activities, business management activities, service offerings, or even for various activities of human life. Kaizen is a regular activity aimed not only for short term production improvements but also humanizes the work place by eliminating overly hard workloads, provided it is practiced correctly throughout the work place. In case you happen to lead a Kaizen team, the following three skills will be helpful for leading a Kaizen successfully.

1. Be the Change

If you want to have a clean workplace, throw the dirty piece of paper fromn the floor in to the dust bin. If you want your team to lessen their chit-chat time, reduce your own frequency and duration for coffee breaks. Keep in mind that your smallest gestures will also be observed and they will affect your team’s attitude. Be the role model and set the example that you want your team to follow. Kaizen is all about bringing small but continuous improvements through the team members to the team to the organization.

2. Be a Real Team Player

From setting the goals to solving problems and achieving improvements, you and your team members should be equally involved. You should be acting like a teacher for generating ideas from your team members. You will be really blessed if you have a team willed with bright, motivated, and talented people. Otherwise, your success as a Kaizen leader will depend totally upon how well you are able to increase the knowledge, skills, and participation of your team members.

3. Communication

Use all modes of communication, including speaking, listening, doing, expressing and appreciating. Your intentions regarding improvements should be well known to your team members and known well in advance. As a Kaizen leader, you should develop a credible reputation that demonstrate to your people that you are there to see them succeed.

What is Kaizen ?

The Japanese word “Kaizen” means “improvement.” The Kaizen philosophy is applied for manufacturing activities, business management activities, service offerings, or even for various activities of human life. Kaizen is a regular activity aimed not only for short term production improvements but also humanizes the work place by eliminating overly hard workloads, provided it is practiced correctly throughout the work place. In case you happen to lead a Kaizen team, the following three skills will be helpful for leading a Kaizen successfully.

1. Be the Change

If you want to have a clean workplace, throw the dirty piece of paper fromn the floor in to the dust bin. If you want your team to lessen their chit-chat time, reduce your own frequency and duration for coffee breaks. Keep in mind that your smallest gestures will also be observed and they will affect your team’s attitude. Be the role model and set the example that you want your team to follow. Kaizen is all about bringing small but continuous improvements through the team members to the team to the organization.

2. Be a Real Team Player

From setting the goals to solving problems and achieving improvements, you and your team members should be equally involved. You should be acting like a teacher for generating ideas from your team members. You will be really blessed if you have a team willed with bright, motivated, and talented people. Otherwise, your success as a Kaizen leader will depend totally upon how well you are able to increase the knowledge, skills, and participation of your team members.

3. Communication

Use all modes of communication, including speaking, listening, doing, expressing and appreciating. Your intentions regarding improvements should be well known to your team members and known well in advance. As a Kaizen leader, you should develop a credible reputation that demonstrate to your people that you are there to see them succeed.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Five Laws of Lean Six Sigma

The Five Laws of Lean Six Sigma have been formulated to provide a path for quality improvement efforts. In addition to this, these laws help in the enhancement of business processes that aim to improve customer satisfaction. These laws have been accumulated by mixing ideas of Six Sigma and Lean Manufacturing.

Five Laws of Lean Six Sigma

1) Zeroth Law: The Law of the Market

The zeroth law acts like the base law and all other laws have been formulated using the principles of this law. This law is the starting point and is rightly indispensable. The law states that “Customer Critical to Quality” defines quality, that is, the main concern for improvement. This is followed by Return on Invested Capital (ROIC) and Net Present Value (NPV).

2) First Law: The Law of Flexibility

The first law states that the speed of any process is comparative to the flexibility or elasticity of the process. This means that more receptiveness of the process and flexibility to adapt to changes better would be the progress of the project implementation.

3) Second Law: The Law of Focus

The second law states that twenty percent of the activities in a process cause eighty per cent of the delay. This law is related to the Pareto Principle. The statement is interpreted as the main cause of delay in activities is originated from twenty percent of activities. This allows a faster re-focus during the re-orientation phase.

4) Third Law: The Law of Velocity

The third law defines the velocity of the process. It states that the process is inversely proportional to the amount of work-in-progress. This ensures that the work is completed in the fastest possible time and delivered promptly. The Law of Velocity is also commonly known as the Little’s Law. The law explains how the inertia of work-in-progress bears heavily on the speed of project implementation. It is important to know; the higher the number of unfinished tasks, the lower would be the speed of progress due to various ground level handicaps.

5) Fourth Law: The Law of Complexity

The fourth law is defined as the complexity of the service or product offering adds more non-value, costs, and work-in-progress than either poor quality or low sigma or slow speed process problems. Thus, the higher the complexity of the job, the more you see excess costs and work being incurred.

Five Laws of Lean Six Sigma

1) Zeroth Law: The Law of the Market

The zeroth law acts like the base law and all other laws have been formulated using the principles of this law. This law is the starting point and is rightly indispensable. The law states that “Customer Critical to Quality” defines quality, that is, the main concern for improvement. This is followed by Return on Invested Capital (ROIC) and Net Present Value (NPV).

2) First Law: The Law of Flexibility

The first law states that the speed of any process is comparative to the flexibility or elasticity of the process. This means that more receptiveness of the process and flexibility to adapt to changes better would be the progress of the project implementation.

3) Second Law: The Law of Focus

The second law states that twenty percent of the activities in a process cause eighty per cent of the delay. This law is related to the Pareto Principle. The statement is interpreted as the main cause of delay in activities is originated from twenty percent of activities. This allows a faster re-focus during the re-orientation phase.

4) Third Law: The Law of Velocity

The third law defines the velocity of the process. It states that the process is inversely proportional to the amount of work-in-progress. This ensures that the work is completed in the fastest possible time and delivered promptly. The Law of Velocity is also commonly known as the Little’s Law. The law explains how the inertia of work-in-progress bears heavily on the speed of project implementation. It is important to know; the higher the number of unfinished tasks, the lower would be the speed of progress due to various ground level handicaps.

5) Fourth Law: The Law of Complexity

The fourth law is defined as the complexity of the service or product offering adds more non-value, costs, and work-in-progress than either poor quality or low sigma or slow speed process problems. Thus, the higher the complexity of the job, the more you see excess costs and work being incurred.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Monday, 24 August 2009

Lean Versus Six Sigma

Six Sigma is problem focused with a view that process variation is waste. Lean Thinking, on the other hand, is focused on process flow and views any activity that does not add value as waste. Six sigma uses statistics to understand variation. Lean uses visuals: process mapping, flowcharting, and value stream mapping, to understand the process flow.

Taiichi Ohno is credited with creating the Toyota Production System (TPS), which is one of the better known implementations of Lean Thinking anywhere in the world. The concepts of lean were born out of the severe resource constraints in postwar Japan, which leads us to next week’s process improvement program - Theory of Constraints.

Lean Thinking is ideal for mature (energy), slow growth (automotive), low transaction industries (small business) or an organization where mathematical tools are not common. Lean begins to use systems thinking and considers all of the process interactions.

But lean is still a reductionist approach focused on eliminating waste (cutting costs). What is needed is to balance the resources released through Lean or Six Sigma improvement programs with an increase in throughput and need for resources. Otherwise you enter a cost cutting, job losing cycle and your process improvement program will grind to a halt.

If you are in a mature, slow growth, low transaction, or non-math business then Lean Thinking will work real well for your organization.

So what’s left? Six Sigma and Lean use two different approaches to get the same end result – process improvement. The Theory of Constraints (throughput improvement) takes the concepts of Lean Thinking to another level of systems thinking.

Labels:

Kaizen,

Lean,

six sigma,

six sigma - MBB,

Templates

Thursday, 20 August 2009

Four Qualities That Identify a Successful Six Sigma Belt Candidate

Six Sigma is a process that needs the human element to exercise. To bridge the gap between mediocrity and excellence there are four critical characteristics to look for in potential candidates who will take the process and execute to a level of performance that will drive dramatic, sustainable results. These are learning ability, leadership, desire and determination. Let us break each of these characteristics down and provide some factors to consider.

Learning Ability

This particular characteristic has been the primary focus, and at times the only one considered for many organizations choosing their Six Sigma Belt candidates. To compound this issue, the focus is generally geared to only those having prior experience with statistics. While this quality is important, it is not the determining factor. A candidate must be able to understand instructions and underlying principles with the ability to reason and make sound decisions possessing an analytical mindset. The ability to gather, analyze and summarize data in order to draw rational, fact-based conclusions is needed. A Six Sigma Belt candidate will be placed in a learning environment where mathematical science is discussed and instructed. Statistical reasoning is needed for proper understanding and execution of the Six Sigma DMAIC method.

Leadership

A candidate must have demonstrated leadership in a team environment with the ability to mentor team members to achieve a level of knowledge that fosters cultural growth and individual project success. The candidate usually knows what must be done and how to get it done, but genuinely involves others and listens to their concerns and ideas. He or she is willing to change course as a result in order to achieve greater results. This person can convince others to follow his/her lead despite skepticism, and is generally able to win the hearts and minds of others to achieve breakthrough objectives. The candidate works collaboratively with fellow employees at all levels of the organization and is able to maintain a blameless environment by focusing on issues and facts rather than seeking who is at fault. This quality to lead and inspire others to achieve a common goal is paramount for Six Sigma success.

Desire

Strong intention or aim for excellence is another characteristic to be considered. A candidate must possess the trait of motivation that has been demonstrated in past performance. The ability to be proactive with foresight to undertake strategic actions aligned with organizational goals is important. The ability to plan and execute work that is accurate, complete, timely and reliable while never compromising integrity shows that the candidate takes pride in all that he or she does. This personal desire for excellence is a good indicator that the candidate will apply the same for anything he or she undertakes. As a company searching for the right Six Sigma Belt candidate it is necessary to communicate the positive education in this continual improvement methodology and the personal growth experience that the candidate will receive. This understanding will help to stimulate the already existing desire and help facilitate the continuing aim for excellence.

Determination

Once a candidate has been selected and embarking on this Six Sigma journey it is crucial that they are devoting full strength and concentrated attention to achieving results in the short and long term. This focused results orientation will keep the candidate moving toward breakthrough objectives while potentially undergoing immense pressure from outside influences to forego the Six Sigma process and fall back into the traditional methods of operation. The ability to adapt effectively in an environment of change, uncertainty and ambiguity is required. The candidate will implement creative solutions that fall outside of the current paradigm, thus challenging the current standard. This will prompt a strong reaction within the status quo and steadfast determination from the Six Sigma Belt candidate is needed to ensure successful implementation and sustainable results.

In Conclusion: Six Sigma Belt Candidate Must Possess All Four Characteristics

Each of these characteristics discussed are crucial for choosing a candidate that will be successful in completing the rigorous Six Sigma training and certification process. The more important aspect is the continued return that a company receives from this individual as a change agent within their continual improvement journey. To ensure that this takes place the Six Sigma Belt candidate must possess all four described characteristics. Six Sigma is a commitment to a management philosophy that drives for total customer value creation. This commitment is not guaranteed by focusing only on the attribute of possessing an analytical mind. The combined characteristics of learning ability, leadership, desire, and determination are paramount for selecting a successful Six Sigma Belt candidate.

Learning Ability

This particular characteristic has been the primary focus, and at times the only one considered for many organizations choosing their Six Sigma Belt candidates. To compound this issue, the focus is generally geared to only those having prior experience with statistics. While this quality is important, it is not the determining factor. A candidate must be able to understand instructions and underlying principles with the ability to reason and make sound decisions possessing an analytical mindset. The ability to gather, analyze and summarize data in order to draw rational, fact-based conclusions is needed. A Six Sigma Belt candidate will be placed in a learning environment where mathematical science is discussed and instructed. Statistical reasoning is needed for proper understanding and execution of the Six Sigma DMAIC method.

Leadership

A candidate must have demonstrated leadership in a team environment with the ability to mentor team members to achieve a level of knowledge that fosters cultural growth and individual project success. The candidate usually knows what must be done and how to get it done, but genuinely involves others and listens to their concerns and ideas. He or she is willing to change course as a result in order to achieve greater results. This person can convince others to follow his/her lead despite skepticism, and is generally able to win the hearts and minds of others to achieve breakthrough objectives. The candidate works collaboratively with fellow employees at all levels of the organization and is able to maintain a blameless environment by focusing on issues and facts rather than seeking who is at fault. This quality to lead and inspire others to achieve a common goal is paramount for Six Sigma success.

Desire

Strong intention or aim for excellence is another characteristic to be considered. A candidate must possess the trait of motivation that has been demonstrated in past performance. The ability to be proactive with foresight to undertake strategic actions aligned with organizational goals is important. The ability to plan and execute work that is accurate, complete, timely and reliable while never compromising integrity shows that the candidate takes pride in all that he or she does. This personal desire for excellence is a good indicator that the candidate will apply the same for anything he or she undertakes. As a company searching for the right Six Sigma Belt candidate it is necessary to communicate the positive education in this continual improvement methodology and the personal growth experience that the candidate will receive. This understanding will help to stimulate the already existing desire and help facilitate the continuing aim for excellence.

Determination

Once a candidate has been selected and embarking on this Six Sigma journey it is crucial that they are devoting full strength and concentrated attention to achieving results in the short and long term. This focused results orientation will keep the candidate moving toward breakthrough objectives while potentially undergoing immense pressure from outside influences to forego the Six Sigma process and fall back into the traditional methods of operation. The ability to adapt effectively in an environment of change, uncertainty and ambiguity is required. The candidate will implement creative solutions that fall outside of the current paradigm, thus challenging the current standard. This will prompt a strong reaction within the status quo and steadfast determination from the Six Sigma Belt candidate is needed to ensure successful implementation and sustainable results.

In Conclusion: Six Sigma Belt Candidate Must Possess All Four Characteristics